The natural choice

Produktinformation

Det austenitiskt rostfria stålet med beteckning 1.4404 (SS 2348) innehåller förutom krom och nickel även ca 2% molybden. Skillnaden mot 1.4301/1.4307 är förutom molybdenets närvaro högre nickelhalt. Denna typ av rostfritt med högre nickel plus molybden kallas ofta (lite olyckligt) för syrafast men i verklighet motstår stålen angrepp endast i svaga syror. 1.4404 har låg kolhalt vilket betyder att det kan svetsas utan risk för nedsatt korrosionsbeständighet i området intill svetsen. Hållfasthetsmässigt är 1.4404 ungefär likvärdig med de lägre legerade stålsorterna 1.4301/1.4307.

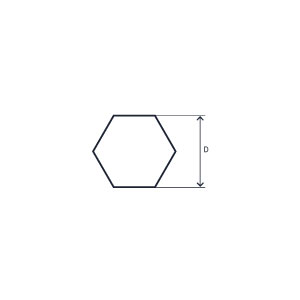

I form av dragen sexkantstång är 1.4404 standardiserat i SS-EN 10088-3. Standarden omfattar kallbearbetad stång med dimensioner upp till 160 mm men normalt är det enbart de mindre dimensionerna som finns tillgängliga i kalldraget utförande. Tibnors program omfattar stång med dimensioner (d v s avstånd mellan motsatta plana ytor) i intervallet 11 - 46 mm.

Tack vare molybdenet ihop med krom uppvisar 1.4404 god motstånd mot korrosion i svaga syror samt vatten som innehåller klorider om nu inte kloridhalten är för hög; ett exempel på en miljö där stålet fungerar bra är den salthaltiga atmosfären nära kusten.

Dragen sexkant av 1.4404 bibehåller ganska bra kallformbarhet trots att duktiliteten har sänkts genom kallbearbetning. Stålet karaktäriseras dessutom av utomordentligt svetsbarhet. Austenitiska stål såsom 1.4404 är allmänt besvärliga att maskinbearbeta men bearbetningen underlättas av för ändamålet anpassade verktyg.

Ytbeskaffenhet på sexkantformat av 1.4404 i lager är 2H såsom den definieras i SS-EN 10088-3. Kalldragning till sexkantformat sker efter att varmvalsad rundstång har glödgats och betats men ändock kan vissa små ytfel kvarstå. Av denna anledning bör den kalldragna ytan inte lämnas obearbetad om detaljen eller konstruktionen kommer att utsättas för hög belastning. Dimensionstoleransen är h11 enligt ISO 286 - 2 som är en noll-minus-tolerans. Med andra ord är dimensionen marginellt mindre än den nominella. Rakheten är god med pilhöjd mindre än 0,001 x längd.